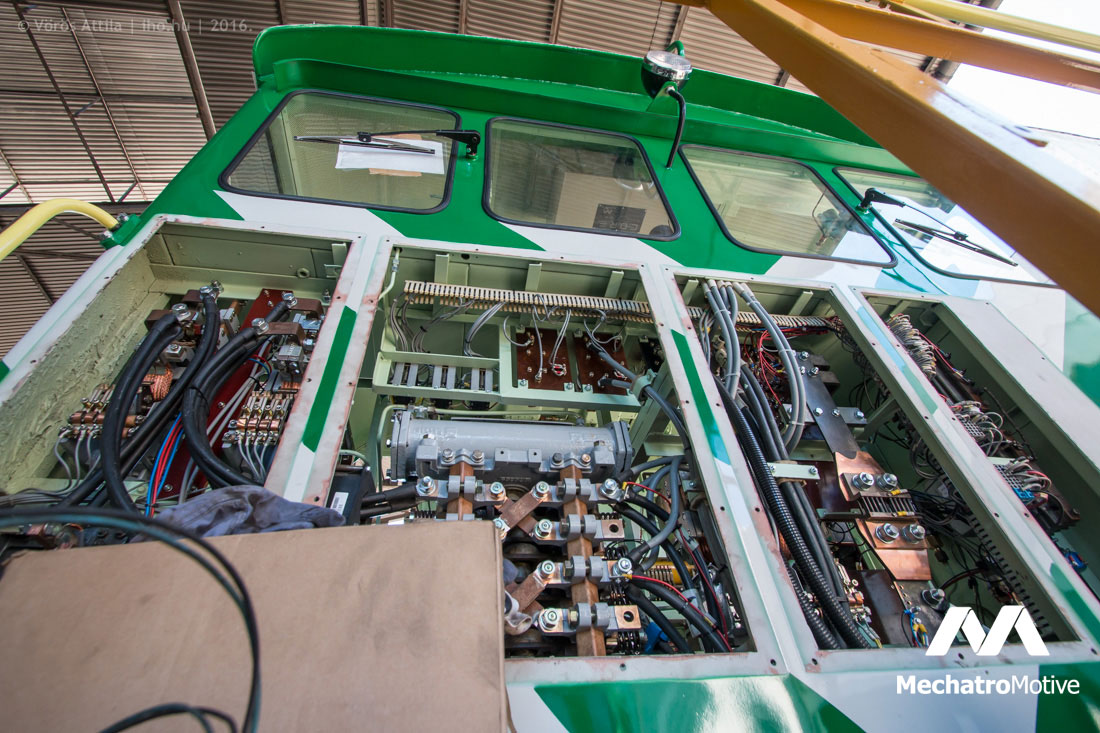

MOL has renewed 7 locomotives. During the program, 7 locomotives are equipped with a brand new diesel engine. Renovate: the chassis, the locomotive cabinet, the bogie, the main generator, all the pneumatic and auxiliary systems, the traction, impact and coupling devices, and the new diesel engines, incorporate a new state-of-the-art control and control system, and the locomotives are polished again.

What changes are to be expected?

New engines have more advanced diagnostics and monitoring systems that are able to communicate with each other, provide real-time feedback on the engine and vehicle data, and collect and store data for further analysis and optimization.

Task of motor diagnostics

The motor diagnostics receives and saves the incoming data to the SD card, communicates with the engine controller and the locomotive control system. An inappropriate operating condition is triggered by an alarm. It also has a PC client that allows real-time engine diagnostics.

What does motor diagnostics measure?

- speed

- acceleration

- cylinder temperature (with thermocouples K)

- air and water temperature

- different pressure values

- generator parameters

- fuel level

Locomotive Monitoring System Functions

Driver identification and engine start using RFID through customizable HMI.

The monitoring system communicates with a server: the server receives the measured data and possible engine error codes.

The system can be used with GPS to determine the vehicle’s instantaneous position, with an accuracy of 1-3 m, which is also suitable for track-accurate positioning, which can be tracked online.

Measuring fuel level is important not only because of later optimization, but the sudden drop in fuel levels will also alert notified persons via email and SMS, so unsuitable usage and theft can be filtered out.

The most important data and possible alarms can also be followed by the driver at the HMI in the driver’s cab.

Other parameters

- The system’s UPS provides 20 minutes of battery power for full operation.

- The wake up function activates the system for predefined events (eg unreasonable fuel consumption).

- The device logs the measured values, which can be analyzed using the customizable vehicle diagnostic software.

- It can communicate with RS232, RS485 and CAN networks, so it can handle other controller data as well as connect to a PC via a USB port.

C.O.R.E. Platform

The C.O.R.E Platform is a universal framework that is easy-to-adapt to the customer’s need. It consists two main units: a PC software and a measuring-controlling unit. The system’s main advantages are the ready-to use components that allow the fast and easy integration of the user-specific items.

Incorporating the systems into the locomotives has helped to rank the better STAGE.

Concepts

DTDMS: “DTDMS is a motor diagnostic and vehicle tracking system used to measure the operating parameters of diesel locomotives, to process, evaluate and transmit data. The data will also be displayed on the vehicle, with a dedicated Human-Machine Interface (HMI).”

HMI: “With a simple system of pushbuttons and signal lights you can contact the user. They can use a text display or a graphical touch screen.”

RFID: “RFID (Radio Frequency IDentification) is a technology used for automatic identification and communication, the core of which is to store and transmit data using RFID tags and devices. The RFID tag is a tiny object that can be fixed or embedded in the object you want to identify. The object can be an object, for example, a commodity or component, or a living being, even a human being.”

Source

- https://mol.hu/hu/molrol/mediaszoba/kozlemenyek?1=1#a-mol-felujittatja-tolatomozdonyait

- http://www.plcprogramozas.hu/mi-a-hmi-

- https://hu.wikipedia.org/wiki/RFID