Upgrading railway systems with IoT solutions

During the years of the 2016 and 2017, MOL renovated 7 shunting locomotives: new engines were installed with new and modern diagnostic and monitoring system that were developed by us and were personalized for the MOL’s unique needs.

The role of MechatroMotive

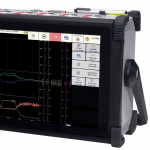

The engine diagnostic system measures the engine’s data, log them to an SD card and it also communicates with the train monitoring system. In case of unexpected operation, it is able to give an alarm. The PC client, that is also part of the system, gives the opportunity for the real-time diagnostic of the engine.

The train monitoring system can measure the current speed of the locomotive and can determine the position of the vehicle with GPS. It is accurate enough to identify tracks. The collected data can be tracked online as well. The measurement of the fuel level is important for later optimizations, and beside of that, the system can alert the designated persons via SMS and email in case of sudden fuel level decrease. It makes possible to notice inadequate use of the locomotive or fuel theft. The monitoring system is connected to a server, which gets all the collected data, and the engine’s fault states.

For safety reasons, it is essential to identify the drivers and to check their permissions. For this, the constant communication between the monitoring system and the server is indispensable. The most important data and notifications can be tracked on an HMI by the driver inside the cab.

The monitoring system is based on our C.O.R.E. Platform as well as the diagnostic system. The C.O.R.E Platform is a universal framework that is easy-to-adapt to the customer’s need. It consists of two main units: a PC software and a measuring-controlling unit.

The system’s main advantages are the ready-to-use components that allow the fast and easy integration of the user-specific items.

The installation of the new systems helped to reach a better STAGE ranking.