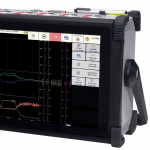

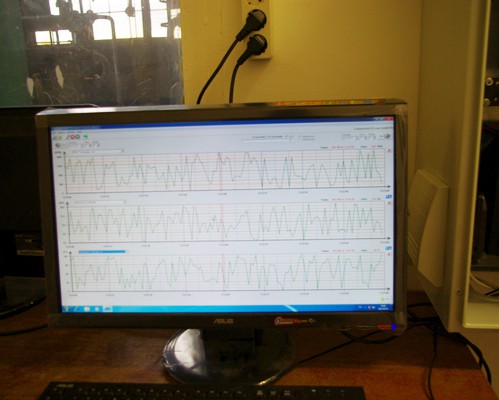

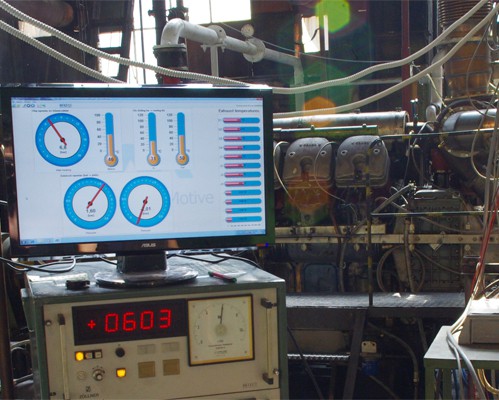

The main purpose of measuring system is continuously collecting, displaying, logging and monitoring parameters of high performance diesel engines.

More than 100 operating parameters (rpm, pressure, temperature, airflow, etc) are simultaneous processing.

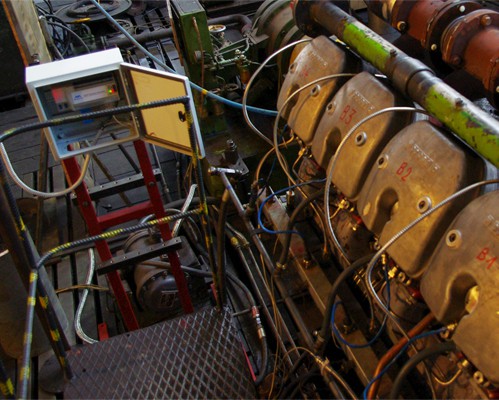

During the design of the system robustness was the decisive criterion. Every device must withstand great environmental impact.

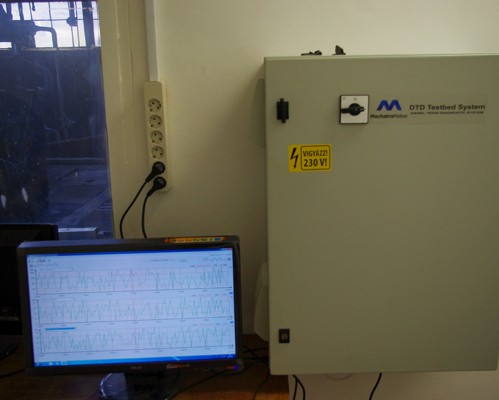

Main information

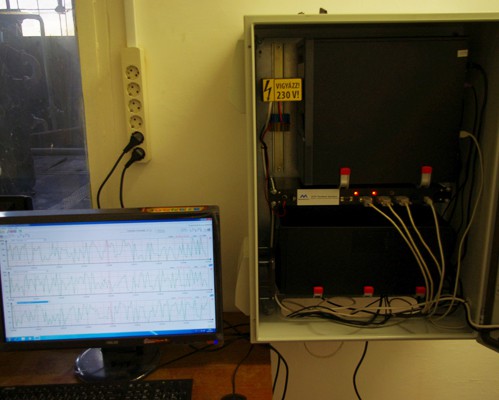

230VAC power supply

Internal voltage 24VDC

20 minute running time with UPS

The measurement equipment is fully isolated

Sensors

Industrial pressure transmitters with 4-20mA output

“K” type thermocouple

PT100 type RTDs

Intelligent air velocity measuring device

Inductive sensors for measuring rpm, up to 5kHz

Communication

Through the RS232 port data request from 3rd Party Devices

USB connection between the PC and measuring system

RS485 connection between the measuring system components

Data processing

Synchronized data is collected every second

Defining alert values for each parameter